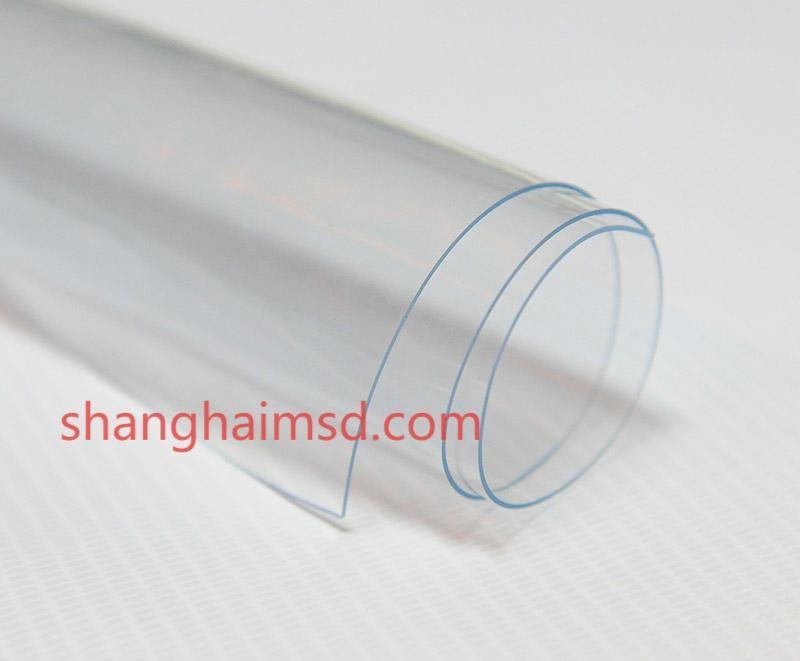

Transparent PVC Film with Anti-Blocking Performance

In applications where transparent films are frequently touched, folded, or stacked, surface behavior becomes as important as optical clarity. For users working with MSD PVC Super Clear Film, smoothness, anti-blocking performance, and tactile consistency directly influence usability across packaging, protective coverings, and interior surfaces. A visually clear film that performs poorly during handling can disrupt processing efficiency and reduce overall application value.

Surface performance begins with formulation design. Additives that control slip, reduce static buildup, and prevent layer adhesion are integrated into the PVC matrix or applied as surface treatments. These components must be carefully balanced to avoid compromising transparency. Excessive slip additives can reduce surface clarity, while insufficient anti-blocking performance may cause films to adhere during storage. Shanghai Ming Shida International Trading Company places emphasis on optimizing surface behavior to ensure films remain easy to separate, position, and process.

Manufacturing conditions strongly affect final surface quality. During calendering, roller finish and pressure uniformity determine surface smoothness and gloss. In extrusion processes, die condition and cooling consistency influence micro-texture development. A stable process minimizes surface defects such as flow marks or uneven gloss, which can detract from the film’s visual appeal and functional performance. Controlled processing ensures that the surface remains uniform across large production runs.

Tactile properties play a significant role in user perception. A well-produced super clear PVC film offers a soft yet controlled touch, avoiding excessive tackiness that can attract dust or fingerprints. In consumer-facing applications such as table covers or document protectors, pleasant surface feel enhances usability. For industrial and commercial environments, controlled friction allows the film to stay in place without slipping excessively during use.

Anti-blocking performance is particularly critical during storage and transportation. Films are often rolled or stacked, and insufficient separation resistance can lead to handling difficulties or surface damage. Anti-blocking agents create micro-spacers that prevent direct surface contact between layers. Testing involves measuring peel force and separation behavior under controlled pressure and temperature conditions. Reliable anti-blocking properties improve efficiency throughout the supply chain.

Electrostatic behavior also affects surface performance. Static charge accumulation can attract dust and particles, reducing visual clarity and complicating handling. Anti-static treatments help dissipate surface charges, keeping the film clean and visually consistent. This is especially important in indoor environments where air movement and low humidity increase static buildup. Controlled electrostatic performance contributes to a cleaner appearance and improved user experience.

Testing methods for surface characteristics include slip coefficient evaluation, surface roughness measurement, and abrasion resistance testing. These assessments help ensure that surface treatments remain effective without degrading transparency or mechanical properties. Abrasion testing is particularly relevant for applications where repeated contact is expected, as it evaluates the film’s ability to maintain clarity and smoothness over time.

Surface durability must align with real-world use conditions. Cleaning agents, repeated wiping, and environmental exposure can gradually alter surface behavior. Well-designed surface treatments resist degradation and maintain consistent performance. Shanghai Ming Shida International Trading Company works with manufacturing partners to ensure that surface properties remain stable throughout the product’s service life.

As transparent film applications continue to expand, surface performance remains a defining factor in material selection. By refining surface treatment strategies and validating performance through targeted testing, super clear PVC film can meet diverse handling and usage requirements. Further information on material characteristics and application insights is available at https://www.shanghaimsd.com/news/industry-news/pvc-super-clear-film-the-ultimate-transparent-solution-for-versatile.html .

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Παιχνίδια

- Gardening

- Health

- Κεντρική Σελίδα

- Literature

- Music

- Networking

- άλλο

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness