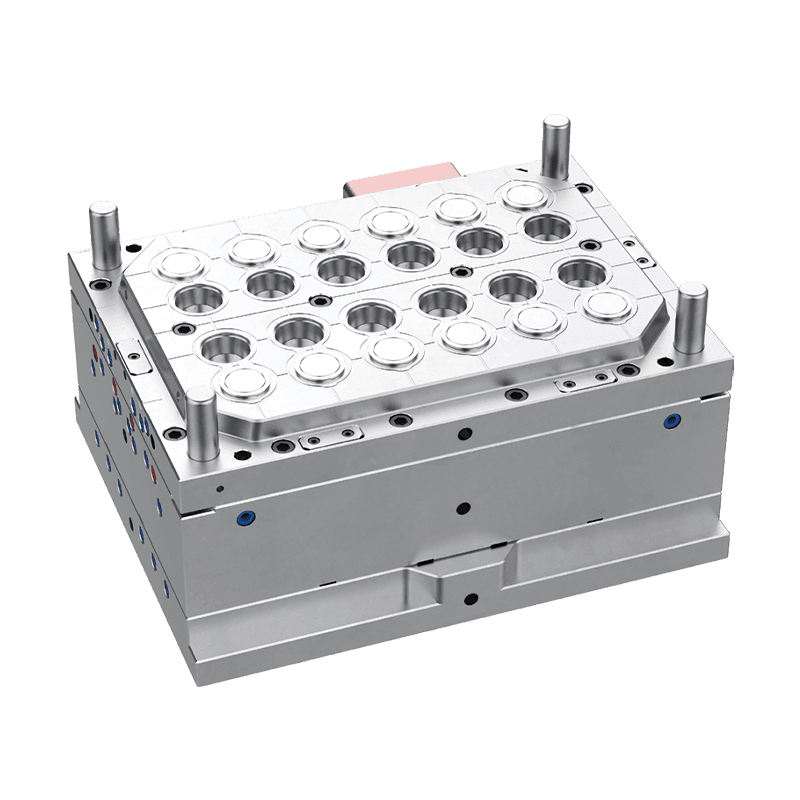

Plastic Food Container Mould:High-Quality Moulding Process

Plastic food container moulds are designed to produce containers with high precision, ensuring that each container is uniform in size, shape, and volume. Consistent moulding is critical in food storage, as any variation in the shape or size could affect the overall packaging process. High-quality moulds maintain tight tolerances and reduce defects during production, leading to fewer rejected items and better operational efficiency.

Reduced Scrap and Waste

A well-performing mould results in fewer defective containers, reducing material waste. This not only contributes to cost savings but also supports more sustainable manufacturing processes, which is an important concern for environmentally conscious users.

Durability and Material Compatibility

Strong and Long-Lasting Moulds

Plastic food container moulds are typically made from high-quality steel or other durable materials to withstand high pressure and repeated use. A strong mould ensures that containers can be produced over long production cycles without compromising performance. This longevity reduces the need for frequent maintenance and replacements, lowering long-term costs.

Suitable for a Range of Plastics

Plastic food container moulds are designed to be compatible with a variety of food-safe plastics, such as PET, PP, and HDPE. Their versatility allows manufacturers to select the most suitable material for the type of food they are packaging, ensuring the containers maintain strength, flexibility, and durability.

Cost-Effectiveness and Efficiency

Faster Production Cycles

A high-performance plastic food container mould speeds up production cycles, which improves manufacturing efficiency and lowers per-unit production costs. Quick cycle times allow manufacturers to produce a larger quantity of containers in less time, contributing to better profitability.

Low Maintenance and Operational Costs

Due to their durability and ease of maintenance, these moulds require minimal downtime. The longevity and low wear and tear of high-quality moulds result in fewer disruptions in production and reduce the overall cost of operation, making them a cost-effective option for food packaging manufacturers.

https://www.food-container-mold.com/product/sauce-cup-mould-series/integrated-sauce-cup-mold-1oz5oz.html

The Disposable Plastic Integrated Sauce Cup Mold (1OZ-5OZ) is a high-quality mold designed for the production of disposable sauce cups ranging from 1 ounce to 5 ounces. This mold is essential for manufacturers aiming to produce uniform, high-precision disposable sauce cups efficiently. Constructed with durable materials, the mold ensures longevity and consistent performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jocuri

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Alte

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness